Products You May Like

We urgently need to move away from fossil fuels, but electric vehicles and other green technology can put their own pressures on the environment. That pressure could be eased with a new magnet design, free from rare-earth metals, that was built with AI in just three months.

Rare-earth metals are essential components in modern-day gadgets and electric tech – including cars, wind turbines, and solar panels – but getting them out of the ground costs a lot in terms of money, energy, and environmental impact.

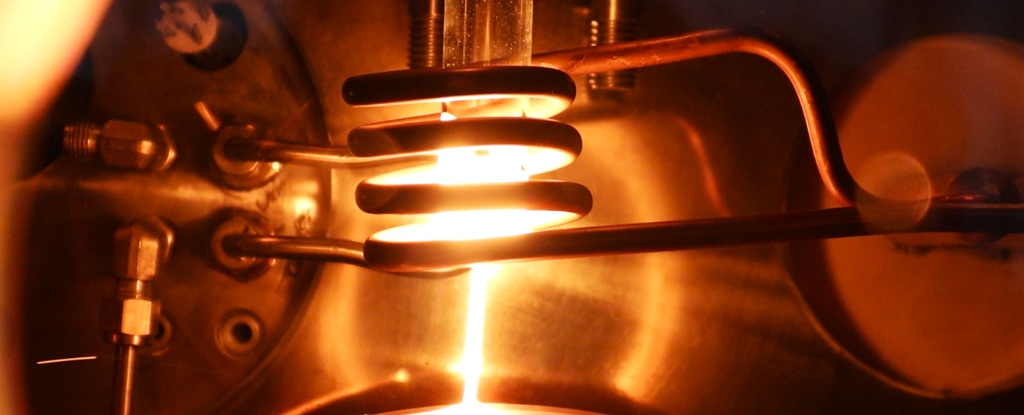

As a result, technology that doesn’t use these metals can help us transition towards a greener future more quickly. Enter UK company Materials Nexus, which has used its bespoke AI platform to create MagNex, a permanent magnet requiring no rare-earth metals.

This isn’t the first such magnet to be developed, but discovering these materials typically requires a lot of trial and error and can take decades. The use of AI sped everything up by approximately 200 times – in just three months, it had designed, synthesized, and tested the new magnet.

The AI works by analysing over 100 million compositions of possible rare-earth-free magnets, weighing up not only the potential performance but also supply chain security, cost to manufacture, and environmental issues.

“AI-powered materials design will impact not only magnetics but also the entire field of materials science,” says physicist Jonathan Bean, the CEO of Materials Nexus.

“We have now identified a scalable method for designing new materials for all kinds of industrial needs.”

Materials Nexus partnered up with a team from the Henry Royce Institute at the University of Sheffield in the UK to produce the magnet, and it’s thought that similar techniques could be used to develop other devices and components free of rare-earth magnets.

According to the makers of MagNex, compared with conventional magnets, the material costs are 20 percent what they would otherwise be, and there’s also a 70 percent reduction in material carbon emissions.

In the electric vehicle industry alone, the demand for rare-earth magnets is expected to be ten times the current level by 2030, according to Materials Nexus – which indicates just how important these alternative materials have the potential to be.

As well as using AI to make manufacturing processes more efficient, researchers are busy trying to find ways to collect rare-earth materials in more sustainable ways. Breakthroughs like this should speed up the move away from fossil fuels and CO2 emissions.

The AI industry has its own challenges when it comes to CO2 emissions, of course. On its current trajectory, it’s predicted to consume 3.5 percent of global electricity by 2030. If AI’s carbon footprint can be managed, it could prove a powerful tool in a green tech transition.

“This achievement showcases the bright future of materials and manufacturing,” says materials scientist Iain Todd, from the University of Sheffield.

“The next generation of materials, unlocked through the power of AI, is highly promising for research, industry, and our planet.”