Products You May Like

Our reliance on plastic has become a huge problem, which is why researchers are excited about a new type of material – one that comes with built-in biodegrading capabilities, due to the bacterial spores living inside it.

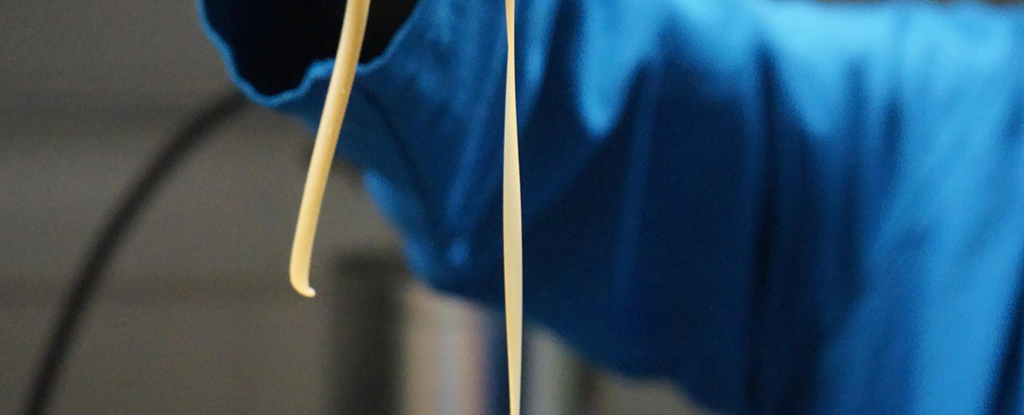

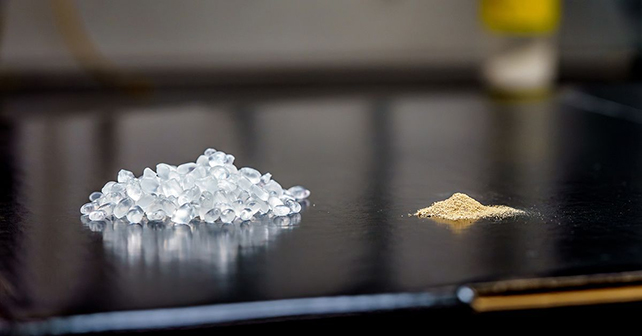

The new self-digesting plastic combines thermoplastic polyurethane (TPU) and Bacillus subtilis bacteria, which had to be engineered to survive the high temperatures involved in plastic production.

By repeatedly exposing the spores to increasing levels of heat, the team of researchers behind this new work found that the bacteria could eventually cope with the temperatures of 135 degrees Celsius (275 degrees Fahrenheit) required to mix the bacterial spores and TPU together.

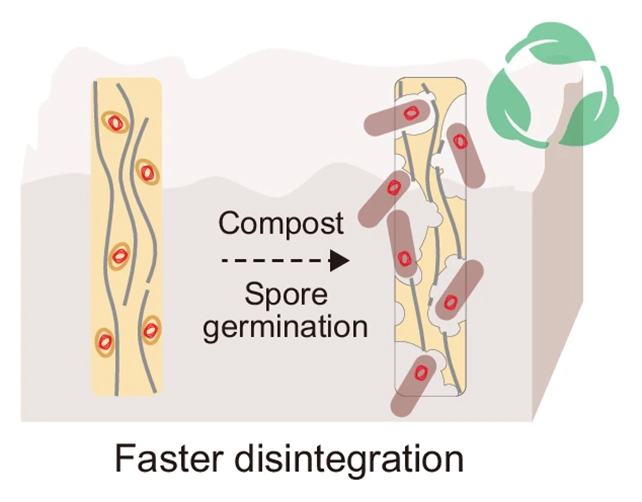

Past efforts to find ways to degrade plastics, fast, have often sourced bacterial enzymes and fungi from soils and compost heaps where those microbes are naturally abundant. But this new material needs only the bacterial spores inside it, reawakened with some nutrients and moisture, to start breaking down.

“What’s remarkable is that our material breaks down even without the presence of additional microbes,” says Jon Pokorski, a polymer scientist at the University of San Diego (UC San Diego) who led the team.

“Chances are, most of these plastics will likely not end up in microbially rich composting facilities. So this ability to self-degrade in a microbe-free environment makes our technology more versatile.”

The research involved several important stages, starting with choosing B. subtilis. It’s a type of bacteria that has previously been linked to the breaking down of plastic, and it can survive in a dormant state without the usual supplies of food and energy.

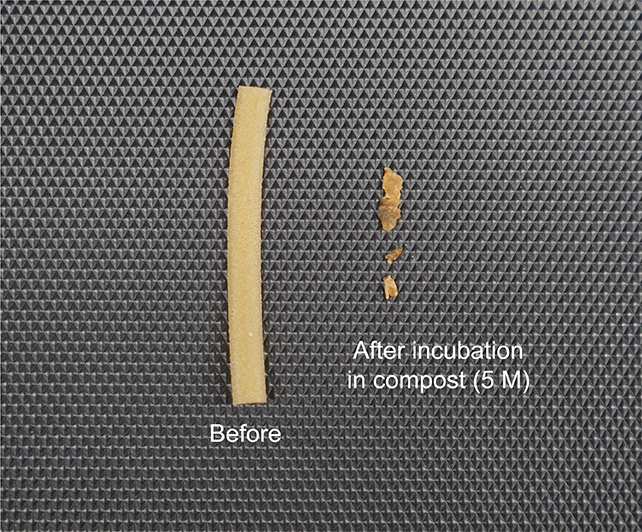

Another stage was testing the decomposition rate of the new plastic: In ideal composting conditions, which reawakened the bacteria from their dormant state, 90 percent of the plastic had disappeared in five months. There were positive signs that some level of degradation could occur in less ideal conditions too.

This could be key when it comes to disposing of such a plastic, if it were to be commercially developed. Research shows that not all ‘compostable’ plastics break down as advertised.

What’s more, in addition to making the plastic biodegradable, the researchers also found the bacteria spores made the material some 30 percent stronger, as well as adding to its stretchability.

“Both of these properties are greatly improved just by adding the spores,” says Pokorski. “This is great because the addition of spores pushes the mechanical properties beyond known limitations where there was previously a trade-off between tensile strength and stretchability.”

TPU is used extensively in all kinds of products, from phone cases to car parts, but there’s currently no effective way of recycling it. As plastic production increases at a rapid rate, we’re in urgent need of ways to limit how much of it gets dumped in the environment.

There’s plenty of scope for future research here: from making sure that the bacteria left behind after decomposition is harmless, to experimenting with different combinations of plastics and bacteria, and scaling up the whole process.

Other researchers are meanwhile trying to make plastics that aren’t made from fossil fuels such as crude oil or their derivatives.

“There are many different kinds of commercial plastics that end up in the environment – TPU is just one of them,” says Adam Feist, a bioengineer at UC San Diego.

“One of our next steps is to broaden the scope of biodegradable materials we can make with this technology.”

The research has been published in Nature Communications.