Products You May Like

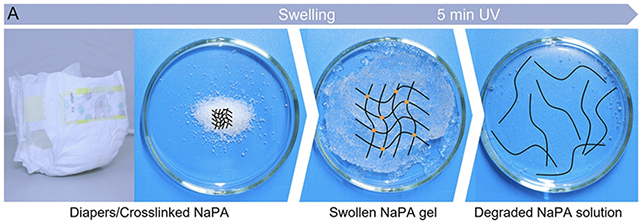

Diaper waste is a real problem, with an estimated 300,000 of them disposed of every single minute worldwide. Now, scientists may have come up with a solution: a process of turning a key part of these diapers into recyclable liquid in just five minutes.

The team behind the innovation, from the Karlsruhe Institute of Technology (KIT) in Germany and Xi’an Jiaotong University in China, used ultraviolet (UV) light to break down a key part of the diapers, without any extra chemicals required – just water.

Specifically, the researchers focused on special polymers called superabsorbers, that (as the name suggests) handle the absorption of liquid. These polymers can be found in other hygiene and medical products too, including bandages.

“The chains that link the polymers are broken by the light,” says Pavel Levkin, a professor of multifunctional materials systems at KIT. “Then, they are so loose that they swim in water and turn into liquid fibers.”

“This method with UV light is about 200 times faster than with acids.”

A 2021 study found acids can be used to break the polymer chains so that the material itself can be broken down. However, it’s difficult and expensive to do, which is why around two million tons of superabsorbers are burned or put in landfill every year.

In the newly developed process, after the liners were cut out of the diapers, they were soaked with water and exposed to a 1000W UV lamp. In just minutes, the material turned into a liquid that could be dropped into a collecting device.

UV light is already well known for being able to degrade materials, as the molecules in a surface absorb the UV energy, disrupting the chemical bonds between them. However, the degradation effects and their speed can vary a lot, depending on the material.

In this case, the researchers were inspired by an earlier study into chemical recycling of superabsorbers, using their knowledge of UV light reactions to hypothesize that the recycling process could be sped up – which it was, significantly.

The substance left over from the recycling process could be used in a number of ways, the researchers suggest, including as a thickener for water-based dyes, or as a component in different types of adhesives. Importantly though, they wouldn’t be going to landfill.

The superabsorber is only part of a diaper, of course, but this is a step in the right direction when it comes to our plastic pollution issues, and the team is confident that the process can be scaled up with reasonable ease.

“This will significantly reduce environmental pollution and contribute to a more sustainable use of polymers,” says Levkin.

The research has been published in ACS Applied Materials & Interfaces.