Products You May Like

Longer-lasting, more efficient batteries would be a boost for everything from smartphones to electric vehicles, and scientists have now made an unexpected discovery that could help develop next-gen battery tech, as well as faster catalysts and other advanced materials.

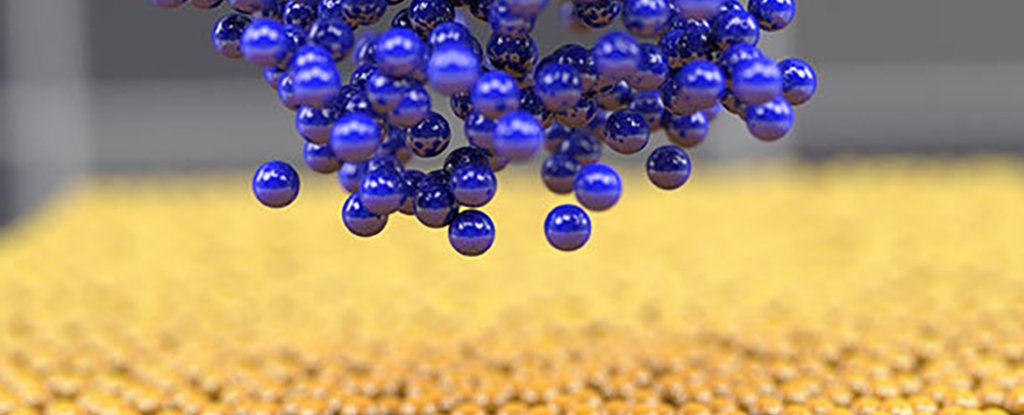

An analysis of the very earliest stages of lithium battery charging – known as nucleation – has shown that slowing electrical currents near the electrode creates disorganised patterns of atoms, which in turn improves the overall charging behaviour.

Through a combination of detailed electron microscopy, liquid-nitrogen cooling, and computer modelling, the researchers were able to observe a noncrystalline ‘glassy’ form of lithium metal as the charging progressed.

“The power of cryogenic imaging to discover new phenomena in materials science is showcased in this work,” says materials scientist Shirley Meng from the University of California San Diego (UCSD).

“True teamwork enabled us to interpret the experimental data with confidence because the computational modelling helped decipher the complexity.”

It’s the first time that a pure metal has been observed in an amorphous form – one much less structured than would normally be expected from the battery-charging process.

Lithium atoms are deposited on the battery anode as it recharges, but the finer details of how this process works at the atomic level aren’t yet fully understood.

What we do know is that the pattern of deposits can vary between charges, leading to a less stable charging process and a gradual degradation of the battery.

In the research, the glassy lithium embryos remained unstructured and loose during their growth as the battery recharged. Both the creation of the glassy metal and the conditions needed for it to form surprised the scientists.

“We can make amorphous metal in very mild conditions at a very slow charging rate,” says materials scientist Boryann Liaw from the Idaho National Laboratory. “It’s quite surprising.”

The computer modelling confirmed that the kinetic reactions were creating amorphous (rather than ordered) crystalline forms with a slow charging speed. Further tests on four more reactive metals replicated the result.

Anywhere that a glassy metal material could be used and adapted is potentially in line to benefit from this research – and that includes getting the same amount of battery energy in a smaller sized package (very handy when you’re wanting your electric car to last as long as possible on the open road).

The glassy metal structures observed in this study are typically very difficult to produce, which makes their appearance here all the more fascinating – and with further research the potential applications could eventually go beyond batteries.

“The properties of such metallic glasses, the amounts, and the particle sizes and distributions could be tuned by adjusting the current density and deposition time through optimisation,” write the researchers in their paper.

“These new amorphous active metals will open new opportunities in various applications besides the metallic glass and energy storage fields, including biomedicine, nanotechnology, and microelectromechanical systems.”

The research has been published in Nature Materials.